PROUD OF ALL OUR PRODUCTION

The origin of the milk we process is closely linked to land, livestock chain Zucchelli is located within a radius of only 8 km from the dairy.

The close spatial relationship with the raw material is a prerequisite for the production of raw milk cheeses, the origin and quality of milk characterized predominantly the final product.

Daily collected milk arrives at the dairy and is allowed to stand for about 12-13 hours.

In this period, known as outcrop, it has the natural separation of milk fat from the fat. It thus forms a surface layer of cream intended for butter making.

Since skim milk begins making cheese Grana.

Since skim milk begins making cheese Grana.While the milk is heated, the double bottoms of copper up to 32 ° C, are added lactic ferments or the whey and curd.

Our whey is recreated daily in a natural way, passing the cheese its typical characteristics of our production.

During processing the cheese maker interprets and evaluates the performance of the same, bringing the curd to final cooking at 54 ° C.

After the processing, is left precipitate the cheese mass at the bottom of the boiler where it will rest in the whey for about 60 minutes.

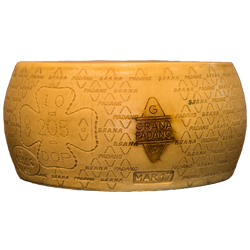

Once extracted the two forms from the boiler is put into a bundle of linen placed in a mold (mold, ed) to assume the characteristic cylindrical shape.

At a later stage of the cheeses are turned every 3 hours. The next day they are placed in brine for salting operation that takes place by immersion in tanks of salt water for about 20/25 days.

After this time the forms are brought in maturing warehouses, where they will remain for a minimum of 15 months before sale.